Page 66 - Azerbaijan State University of Economics

P. 66

THE JOURNAL OF ECONOMIC SCIENCES: THEORY AND PRACTICE, V.73, # 2, 2016, pp. 62-72

functionality - cost - labour - intensiveness.

For measurement of the effectiveness indicators of QMS process it is

necessary to determine the criteria of effectiveness, and significance of these

effectiveness indicators. It is important to select such indicators of the effectiveness

process, which would reliably reflect the process operation and planned results

[Storublev M.L., 2009, -122 p.]. As the effectiveness criteria, we accept:

- the quantity of the non-executed control terms;

- completeness and timeliness of execution of all plans;

- relation of external and internal discrepancies to the quality of services

provided.

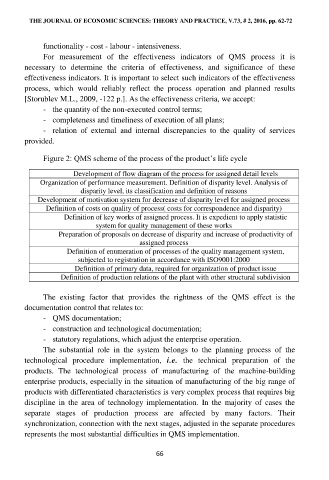

Figure 2: QMS scheme of the process of the product‟s life cycle

Development of flow diagram of the process for assigned detail levels

Organization of performance measurement. Definition of disparity level. Analysis of

disparity level, its classification and definition of reasons

Development of motivation system for decrease of disparity level for assigned process

Definition of costs on quality of process( costs for correspondence and disparity)

Definition of key works of assigned process. It is expedient to apply statistic

system for quality management of these works

Preparation of proposals on decrease of disparity and increase of productivity of

assigned process

Definition of enumeration of processes of the quality management system,

subjected to registration in accordance with ISO9001:2000

Definition of primary data, required for organization of product issue

Definition of production relations of the plant with other structural subdivision

The existing factor that provides the rightness of the QMS effect is the

documentation control that relates to:

- QMS documentation;

- construction and technological documentation;

- statutory regulations, which adjust the enterprise operation.

The substantial role in the system belongs to the planning process of the

technological procedure implementation, i.e. the technical preparation of the

products. The technological process of manufacturing of the machine-building

enterprise products, especially in the situation of manufacturing of the big range of

products with differentiated characteristics is very complex process that requires big

discipline in the area of technology implementation. In the majority of cases the

separate stages of production process are affected by many factors. Their

synchronization, connection with the next stages, adjusted in the separate procedures

represents the most substantial difficulties in QMS implementation.

66